High Capacity Double Deck Vibrating Screen

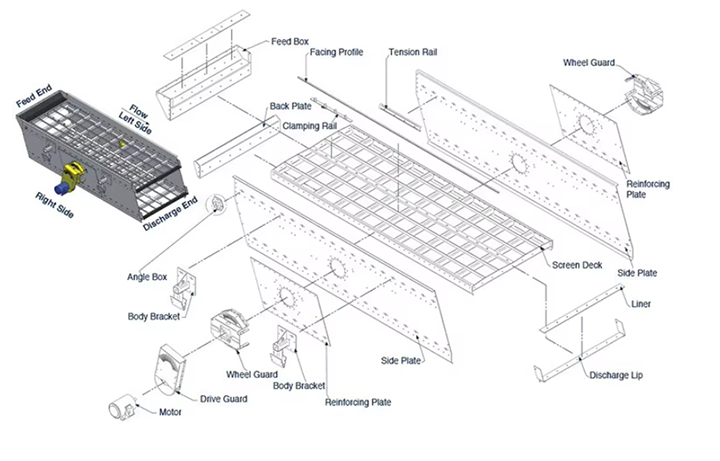

High Capacity Double Deck Vibrating Screen is an industrial screening device used for classifying or separating large quantities of bulk materials such as ores and coal. Its structure consists of a screen box, double-layer screens, a vibrator, vibration damping support devices, and a drive motor. The double-layer screens can separate the feed material into coarse, medium, and fine particle sizes in a single pass, with screen apertures ranging from 0.074mm to over 50mm. The single-unit processing capacity can reach 50-500 tons per hour, and the screening accuracy can be controlled between 90% and 98%. Two common types of equipment are the YK series and the DZSF series.

Working Principle of the High Capacity Double Deck Vibrating Screen

The working principle of the High Capacity Double Deck Vibrating Screen is basically the same in the YK series and DZSF series, but the vibration mode differs. The YK series double-layer vibrating screen uses an eccentric shaft or eccentric block vibrator. After the motor runs, the screen box vibrates in a near-circular manner, causing the material to be thrown up and spread forward on the screen surface. Fine materials pass through the upper and lower screens sequentially for grading, making it suitable for high-volume screening. The DZSF series double-layer vibrating screen uses two vibrating motors rotating synchronously in opposite directions to generate linear vibration. The material moves forward in a jumping, straight line on the screen surface, with the upper and lower screens continuously completing the grading process. This is more suitable for fine particle size and high-precision screening conditions.

What are the advantages of using a High Capacity Double Deck Vibrating Screen?

The double-layer screen design of the High Capacity Double Deck Vibrating Screen effectively provides twice the screening area within the same floor space, increasing capacity per unit time. A single unit can simultaneously produce products of three particle sizes, simplifying the process and saving on equipment investment and space. The powerful vibration makes it less prone to material clogging, resulting in a clear screening process. The structure utilizes heavy-duty box beams and high-quality steel plates, welded together to withstand the impact of large materials and continuous high-load operation. This results in smoother vibration during operation, a low failure rate, and a service life of 8-10 years.

High Capacity Double Deck Vibrating Screen Types

Different types of High Capacity Double Deck Vibrating Screens differ in screening accuracy and output. For example, the YK type is suitable for large-volume and medium-to-coarse material screening, while the DZSF type offers higher screening accuracy. The choice depends on the specific working conditions.

The double-layer YK type circular vibrating screen features a vibrator located above the center of gravity of the screen box. The screen box has a beam structure, providing strong impact resistance. The screen surface inclination angle is 15°-25°. Due to its strong throwing action, it is suitable for processing large-particle, high-density ores requiring rapid loosening and discharge. When processing medium-sized rocks, its throughput per unit area is greater than the DZSF type, processing 100-500 tons of material per hour.

The DZSF type double-layer linear vibrating screen adopts a direct-drive motor, with a screen surface inclination angle of 0°-15°. It offers higher screening accuracy than the YK type and is suitable for dewatering, desliming, desliming, or grading medium and fine-grained materials. When processing dry fine materials within the same particle size range or materials requiring washing, it offers a better balance between screening accuracy and throughput. However, its processing capacity is lower than the YK type circular vibrating screen of the same specification when screening large, high-density materials, with a throughput of 50-200 tons per hour.

High Capacity Double Deck Vibrating Screen Specifications

| Series | Model | Screen Size (mm) | Layers | Capacity (t/h) | Motor (kW) |

| YK Series | 2YK1224 | 1200×2400 | 2 | 20-120 | 5.5 |

| 2YK1235 | 1200×3500 | 2 | 20-150 | 7.5 | |

| 2YK1548 | 1500×4800 | 2 | 200-300 | 15 | |

| 3YK1548 | 1500×4800 | 3 | 250-378 | 15 | |

| DZSF Series | DZSF-520 | 500×2000 | 2 | ≤3 | 0.37×2 |

| DZSF-1020 | 1000×2000 | 2 | ≤12 | 0.75×2 | |

| DZSF-1224 | 1200×2400 | 2 | ≤23 | 1.5×2 | |

| DZSF-1530 | 1500×3000 | 2 | ≤32 | 2.2×2 |

High Capacity Double Deck Vibrating Screen Applications

The High Capacity Double Deck Vibrating Screen can perform pre-screening or inspection screening of ore after the crushing process, used to separate crushed stone and tailings of different particle sizes. In sand and gravel aggregate production lines, it is used to grade the crushed mixture into various sizes of gravel and sand that meet construction standards. In the coal industry, it is used for grading raw coal, desliming, and screening washed products. In industries such as metallurgy, chemicals, building materials, power, road construction, and waste treatment and recycling, this type of screen is suitable for large-capacity bulk material particle size separation.

For high-capacity material screening, the High Capacity Double Deck Vibrating Screen is a good choice. DaHan Machinery, a manufacturer with 15 years of experience in vibrating equipment manufacturing, utilizes CNC cutting and automatic welding to ensure the precision and strength of structural components. The vibrator undergoes dynamic balancing testing, ensuring smooth operation and low noise. The screen box is made of high-strength, fatigue-resistant steel, and different types of screens are available, including woven metal mesh, perforated plates, and polyurethane screen plates. Suitable solutions can be provided based on the specific material characteristics, production capacity requirements, and installation conditions of customers, providing robust and durable equipment for large-scale industrial production.

-

Double deck with incline vibrating screen

Double deck with incline vibrating screen adopts high-quality wear-resistant screen mesh and high-strength steel structure.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Limestone double deck with incline vibrating screen

Limestone double deck with incline vibrating screen utilizes reciprocating vibration provided by an exciter motor or eccentric shaft to cause the material to move...

-

Double Deck Vibrating Screen For Silica Sand

Double Deck Vibrating Screen For Silica Sand is a vibrating screening machine with upper and lower screens for screening silica sand...

-

Double Deck Vibrating Screen For Recycling

Double Deck Vibrating Screen For Recycling uses a vertically stacked design with two layers of screens to simultaneously separate recyclable materials such as plastics...

-

Double Deck Vibrating Screen For Fertilizer

Double Deck Vibrating Screen For Fertilizer is used for grading and removing impurities from granular materials such as compound fertilizers, urea, phosphate fertilizers, and organic fertilizers...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.