Carbon steel vibrating screen

![[field:title/]](/uploads/allimg/250113/6-2501131R11DA-lp.png)

Callback

Carbon steel vibrating screen is a screening equipment widely used in industrial production, mainly used for removing impurities and grading dry powder and granular materials.

| Productivity: | 100 kg – 3 tons/hour |

| Number of layers: | 1-5 layers |

| Mesh size: | 5-500 mesh |

Highly wear-resistant and impact-resistant, suitable for handling large, heavy materials

Rugged structure, suitable for screening medium to coarse-grained materials

What is Carbon Steel Vibrating Screen?

Carbon steel vibrating screen are used to process low to medium corrosivity, high density, dry, or somewhat abrasive industrial raw materials or granular materials. The screening particle size range is between 2 mm and 50 mm, and grading can be achieved depending on the screen configuration. This equipment can achieve screening and particle size separation, while also serving as a material conveyor and loosener, ensuring consistent particle size in the final product.

Carbon steel vibrating screen is a device that uses the principle of vibration to screen granular or powdered materials. Its main structural components are made of carbon steel. Carbon steel is an iron-carbon alloy with a carbon content of less than 2.11%. It has good strength, toughness and processing properties, which enables the carbon steel vibrating screen to withstand a certain material weight and vibration impact.

Carbon steel vibrating screen video

How does Carbon Steel Vibrating Screen work?

Carbon steel vibrating screen generates vibrations through the exciter, causing the screen box to vibrate horizontally or obliquely. The material on the screen surface is affected by the excitation force and gravity, jumping on the screen surface and moving forward. Materials larger than the screen hole are retained on the screen surface, and materials smaller than the screen hole fall through the screen into the next layer or are discharged.

What types of Carbon Steel Vibrating Screens are there?

Circular carbon steel vibrating screens are suitable for screening granules, powders, and finely screening slurries.

Structural features: Both the screen box and screen mesh are circular. This shape of carbon steel vibrating screen results in a relatively symmetrical structure and uniform force distribution during operation.

Motion path: The motion path is relatively regular, which is beneficial for fine screening of materials with small particle size differences.

Advantages: Due to its circular motion characteristics, the material distribution on the screen is relatively uniform, and local accumulation is less likely. It is suitable for filtering slurry materials, and its motion effectively promotes liquid-solid separation and prevents screen clogging.

Application scenarios: Used for screening materials with high precision requirements in industries such as fine chemicals, food, and pharmaceuticals. It is also suitable for filtering and classifying various slurries and suspensions.

Rectangular carbon steel vibrating screens excel at handling large volumes of coarse-grained materials.

Structural features: Utilizing a square screen box and rectangular screen mesh, the structure is robust, with a large effective screening area and high throughput per unit time.

Motion path: The drive system generates strong linear vibration, causing the material to jump forward in a straight line on the screen surface, resulting in high screening efficiency. The four corners are reinforced to effectively cope with stress.

Advantages: Excellent overall strength and impact resistance; effectively breaks up slightly agglomerated materials with initial moisture content; less prone to screen clogging.

Applications: Used in mining, building materials, metallurgy, and other industries; suitable for primary classification and impurity removal of large particles such as coal, ore, and gravel.

Features of Carbon Steel Vibrating Screen

Carbon steel, as a common and relatively inexpensive metal, makes carbon steel vibrating screens cheaper to manufacture than those made of stainless steel or other special alloys. Carbon steel itself possesses good strength and toughness, enabling it to withstand significant impact and material weight. Under normal use and maintenance conditions, carbon steel vibrating screens can operate stably for extended periods without easily breaking down. Through proper vibration parameter settings and screen selection, carbon steel vibrating screens can effectively screen various materials and accurately classify them according to particle size, meeting the production needs of different industries.

Comparison between carbon steel vibrating screen and stainless steel vibrating screen

| Features | carbon steel vibrating screen | stainless steel vibrating screen |

|---|---|---|

| Material | carbon steel | stainless steel (such as 304 stainless steel, 316 stainless steel) |

| Corrosion resistance | poor | good |

| High temperature resistance | general | good |

| Sanitary | poor | good |

| Cost | low | high |

| Application range | mining, building materials, etc. | food, medicine, chemical industry, etc. |

| Scope of application | applicable to occasions with low requirements for material purity and relatively dry working environment | applicable to occasions with high requirements for material purity and harsh working environment |

Specifications of carbon steel vibrating screen

| Specifications | Typical values | Units | Remarks |

|---|---|---|---|

| Screen frame size | 500mm×1000mm, 1000mm×2000mm, etc. | mm | Select according to the processing volume |

| Screen mesh number | 10 mesh, 20 mesh, 40 mesh, 60 mesh, 100 mesh, etc. | mesh | Select according to the particle size of the material |

| Screen material | Carbon steel | - | Wear-resistant and durable |

| Screen frame material | Carbon steel | - | Consistent with the screen material |

| Vibration frequency | 50-150Hz | Hz | Adjust according to the material characteristics |

| Amplitude | 1-5mm | mm | Affects screening effect |

| Screening efficiency | More than 90% | % | Depends on the material properties and the screen mesh number |

| Processing capacity | 1-100 tons/hour | tons/hour | Depends on the equipment model and material properties |

| Motor power | 2.2kW-15kW | kW | Select according to the processing volume |

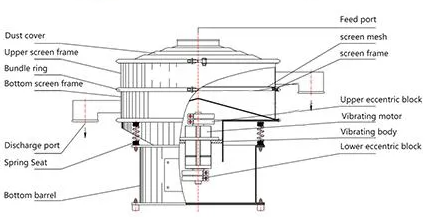

Structure of Carbon Steel Vibrating Screen

The carbon steel vibrating screen consists of a screen box, vibrator, support device, and motor. Each component performs its own function to screen, remove impurities, and filter materials.

Screen box: The screen box is the core component of the vibrating screen, usually welded with carbon steel plates, with high strength and rigidity.

Screen: Installed on the screen box for screening materials. The material, mesh and hole type of the screen are selected according to the characteristics of the material and the screening requirements.

Vibrator: Provides a vibration source, usually an electric vibration motor.

Suspension device: Suspend the screen box on the frame to make the screen box vibrate.

Base: Support the entire equipment and provide an installation foundation.

Parameters of carbon steel vibrating screen

| Model | DH-600 | DH-800 | DH-1000 | DH-1200 | DH-1500 | DH-1800 | DH-2000 |

|---|---|---|---|---|---|---|---|

| Diameter mm | Φ600 | Φ800 | Φ1000 | Φ1200 | Φ1500 | Φ1800 | Φ2000 |

| Screen area ㎡ | 0.24 | 0.45 | 0.67 | 1.0 | 1.6 | 2.43 | 3.01 |

| Screen specification (mesh) | 2-500 | 2-500 | 2-500 | 2-500 | 2-500 | 2-500 | 2-500 |

| Feed Particle size mm | <Φ10 | <Φ15 | <Φ20 | <Φ30 | <Φ30 | <Φ30 | <Φ30 |

| Vibration rpm | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Effective screen surface diameter mm | Φ560 | Φ760 | Φ930 | Φ1130 | Φ1430 | Φ1760 | Φ1960 |

| Number of layers | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Power Kw | 0.25 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 |

Application scenarios of carbon steel vibrating screen

Carbon steel vibrating screens are used for screening dry, bulk materials such as coal, ore, sand, and grain, or for particle size classification and solid-liquid separation. The following are common applications of the product.

Building materials industry: used to screen building materials such as sand and gravel, and separate materials of different particle sizes to meet the requirements of material particle size in construction. For example, in a concrete mixing station, a carbon steel vibrating screen can screen out coarse sand and fine sand that meet the requirements for the production of concrete of different strength grades.

Mining field: Widely used in the preliminary screening and grading of ores. The mined ore can be classified according to particle size to provide suitable raw materials for subsequent beneficiation and processing procedures.

Agricultural processing: used for screening of agricultural products such as grains and seeds. For example, at grain purchasing stations, carbon steel vibrating screens can remove impurities and empty grains from grains to ensure the quality of grains; in seed companies, they are used to screen out plump and uniformly sized seeds to improve the germination rate of seeds.

Carbon steel vibrating screen customer case

Carbon steel vibrating screen supplier

As a supplier of carbon steel vibrating screens, Dahan Machinery understands the critical importance of equipment reliability and durability under harsh operating conditions. Therefore, it selects high-quality carbon steel plates and manufactures the screen body using advanced laser cutting and automatic welding processes to ensure a robust structure and minimal deformation. The screening machines undergo rigorous dynamic balancing calibration to meet the screening needs of large-volume ores and highly abrasive materials. In addition to providing various standard models, Dahan Machinery can also customize designs and production based on specific working conditions, material characteristics, and screening objectives, committed to providing robust and durable products and professional technical support.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Double deck vibrating screen has two layers of screens installed inside.

-

Diamond Vibrating Screen

Diamond vibrating screen is a device used for screening and grading diamond particles. Through vibration force and screen structure ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration, low melting point, ...

-

Sugarcane Juice Bioethanol Vibro Sifter

Sugarcane Juice Bioethanol Vibro Sifter is a device for filtering sugarcane juice, mainly used for sugarcane juice filtration in bioethanol industry. ...

-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.