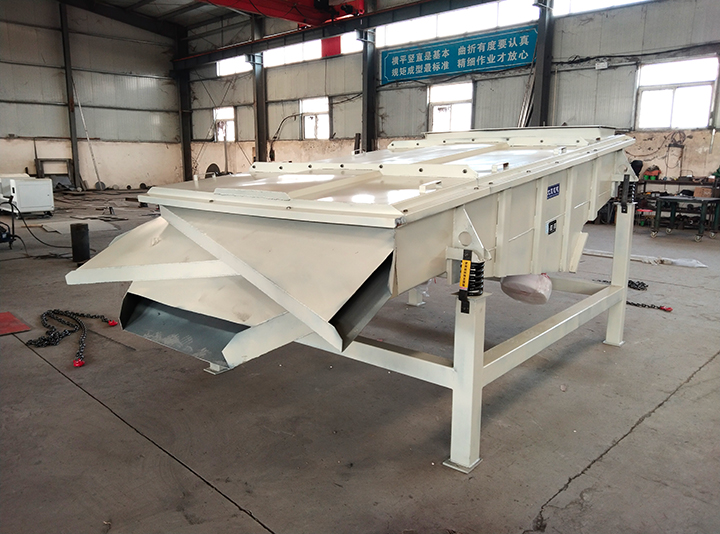

Stamen seed vibrating screen

Stamen seed vibrating screen is a specialized piece of equipment used in the agricultural industry for sorting and cleaning stamen seeds based on their size and quality. The vibrating screen can clean up the unnecessary impurities in the stamen seeds, improve the finished stamen seeds, and can screen a variety of stamen seeds to achieve the purpose of screening. Stamen seeds, also known as pollen grains, are essential for plant reproduction and are often used in breeding programs, research, and seed production. The vibrating screen plays a crucial role in ensuring the purity, uniformity, and quality of stamen seeds used in various applications.

What is the function of the stamen seed vibrator and why is it important

Seed Sorting: The primary function of a stamen seed vibrating screen is to sort and classify stamen seeds based on their size, shape, and quality. This helps in separating viable seeds from debris, damaged seeds, and impurities.

Quality Control: By removing impurities and unwanted particles, the vibrating screen helps maintain the quality and purity of stamen seeds, ensuring that only high-quality seeds are used for breeding or research purposes.

Uniformity: The vibrating screen ensures that stamen seeds are uniformly sized, which is crucial for consistent results in breeding programs, seed production, and research activities.

Stamen seed vibrating screen Working Principle

The stamen seed vibrating screen uses the vibration motor as the vibration source to make the material be thrown up on the screen and move forward in a straight line. The material enters the feed port of the screening machine evenly from the feeder, and produces several specifications of screened and screened materials through the multi-layer screen, which are discharged from their respective outlets.

Applications of Stamen Seed Vibrating Screen

Seed Production: Used for sorting and cleaning stamen seeds in seed production facilities to ensure high-quality seed batches for planting and breeding programs.

Research and Development: Essential for separating stamen seeds in research laboratories and breeding programs to study seed characteristics and genetic traits.

Agricultural Industry: Deployed in agricultural settings for processing stamen seeds used in hybrid seed production, crop improvement, and genetic research.

Stamen seed vibrating screen is a valuable piece of equipment in the agricultural industry for sorting and cleaning stamen seeds based on their size and quality.

Selection recommendations for stamen seed vibrating screens

The selection of stamen seed vibrating screens needs to comprehensively consider factors such as seed characteristics, yield requirements, and screening accuracy. The following are key selection guidelines:

1. Select the type of vibrating screen according to seed characteristics

| Vibrating screen type | Applicable scenarios | Advantages | Limitations |

| Rotary vibrating screen | Small and medium yield, high-precision screening (such as laboratories or breeding centers) | Multi-layer screening (3-5 layers), good sealing, adjustable amplitude, | Relatively small processing capacity |

| Linear vibrating screen | Continuous production, large-yield screening (such as seed processing plants) | Large processing capacity, suitable for coarse screening and grading | Accuracy slightly lower than rotary vibrating screen |

| Ultrasonic vibrating screen | Ultrafine stamen seeds (such as pollen or micron-level seeds) | Anti-blocking net, high precision (up to 500 mesh) | Higher cost |

Stamen seeds are usually small in size and light in weight, and are easily affected by static electricity or humidity, so the type of vibrating screen needs to be selected in a targeted manner:

2. According to the mesh size and material selection

First, pre-cleaning (removal of impurities): 20~60 mesh, which can effectively remove large particles of impurities; second, standard grading: 60~120 mesh, suitable for most stamen seeds; finally, high-precision screening: 120~200 mesh, such as pollen or hybrid breeding seeds. If the seeds are prone to static electricity (such as dry pollen), nylon or anti-static coated screens are preferred. Stainless steel (rust-proof) or polyester screens (corrosion-resistant) are recommended for high humidity environments.

-

Remove lumps and debris in flour, improve flour quality

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Glucose granules vibrating screen

Glucose granules vibrating screen is a specialized piece of equipment designed for sieving and separating glucose granules based on their particle size....

-

PVC stabilizer powder vibrating screen

PVC stabilizer powder vibrating screen is a specialized piece of equipment designed for sieving and separating PVC stabilizer powders based on their particle size......

-

Plastic granule vibration screening machine

Plastic granule vibration screening machine is a device used to screen plastic granules. It mainly achieves material classification and impurity removal by vibration.......

-

Ceramic slurry vibrating screen

Ceramic slurry vibrating screen is a specialized type of vibrating screen designed for filtering and separating ceramic slurries in industrial processes. ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.