Stainless steel sieve for filter milk

What is stainless steel sieve for filter milk?

The stainless steel sieve for filter milk is a screening equipment for milk filtration, mainly made of 304 or 316 food-grade stainless steel. The filter sieve removes solid particles such as clots and impurities in milk through fine metal mesh. The sieves are mostly woven mesh structures, with common sieving mesh numbers ranging from 80 to 200 (apertures of about 180 μm to 75 μm). Different mesh numbers can be selected according to the viscosity of the milk and the filter requirements. The higher the mesh number, the finer the filter effect, and the impurities in the milk, such as milk skin and sediment, can be effectively removed. Suitable for scenes such as dairy processing plants, ranches, and small milk stations, it can perform preliminary or fine filter of raw milk to improve the purity of milk and lay the foundation for subsequent processing or storage.

What is the main function of stainless steel sieve for filter milk?

The main function of a stainless steel sieve for filter milk is to remove visible impurities from milk, such as feed residue, animal hair, grass clippings, and other tiny solid particles. Through physical interception, it improves the purity and taste of the milk.

Sediment and debris: dust, dirt, straw and other foreign matter that may enter the milk during milking or handling.

Animal hair: loose hair of cows or other animals.

Condensed milk solids: small pieces or clots that may form.

Bacteria and spores: Although not the main target of all basic filters, some finer stainless steel mesh filters, especially when used in membrane filtration systems, can help reduce microbial loads.

Fat globules: In some specific filtration processes, such as microfiltration, stainless steel membranes are used to separate fat from milk.

Types of stainless steel sieve for filter milk

The stainless steel sieves used for milk filtration are usually fine metal mesh structures that can effectively intercept larger solid impurities in milk, such as milk lumps, impurity particles, etc., while ensuring the flow rate and filtration efficiency of milk.

Linear vibrating screen

Linear vibrating screen is mostly used as a coarse screen when filtering milk, which is suitable for removing larger particle impurities (such as milk residue and suspended matter). Its screening mesh is usually 20-100 mesh, which is used for milk of different concentrations and temperatures. It can effectively improve the purity and quality of milk. The yield rate varies depending on the impurity content, and can generally be maintained at more than 95%. The exciting force generated by the vibration motor causes the screen to produce linear motion, thereby achieving the screening of milk.

Filter screen

Filter screens are generally fine screens, which are used to filter suspended matter and impurities in milk. The impurities are trapped by the gravity and pressure of the milk using the aperture size of the screen. The screening mesh is usually set between 30 and 80 meshes to meet different filtering needs. The yield rate can reach more than 98%, and the screening output can reach several thousand liters per hour according to the equipment design. The equipment has high precision and good filtering effect, and is often used for fine filtering of pasteurized milk, yogurt and other products.

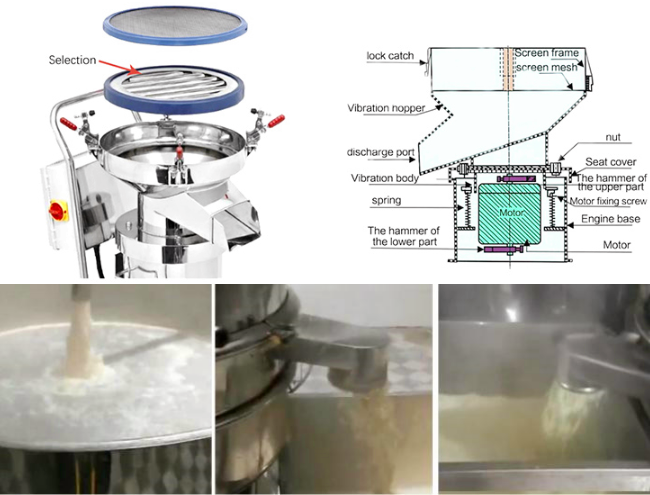

Rotary Vibrating Screen

The rotary vibrating screen has both coarse and fine screening functions when used for milk filtration. Different precision requirements can be achieved by replacing the screen (coarse screen 20-80 mesh, fine screen 100-200 mesh). Its output decreases with the increase of mesh number. It can reach 5-10 tons per hour for coarse screening and about 1-3 tons per hour for fine screening. The yield rate is stable at 95%-98%. The milk makes a spiral diffusion movement on the screen surface, and large particles of impurities are discharged from the upper discharge port, and fine impurities are separated through the screen. The equipment has high screening efficiency and is suitable for dairy factories to grade and filter different types of milk.

Main components and materials of stainless steel filter sieve

The stainless steel sieve for filtering milk resists the corrosive effects of moisture and milk fat, preventing rust and contamination. Furthermore, the smooth surface of stainless steel makes it difficult for residues to adhere, facilitating cleaning and sterilization, meeting food safety and hygiene requirements, and ensuring the pure quality of dairy products.

Material: Generally, 304 or 316 food-grade stainless steel is used, which is corrosion-resistant, high-temperature-resistant, and not easy to rust, and is suitable for contact with liquid dairy products.

Structure: The sieve surface is usually a fine mesh to intercept solid impurities in milk, such as clots, milk residues, etc.; the supporting structure is strong to ensure mechanical stability during the filtration process.

Shape and specifications: There are many shapes such as flat sieves, cylindrical sieves, disc sieves, etc. The aperture size can be selected according to needs, and the common aperture range is from tens of microns to hundreds of microns.

What are the advantages of stainless steel sieve for filter milk?

The stainless steel sieve for filter milk provides a variety of mesh options (100-400 mesh, pore size 0.15mm-0.037mm), which can accurately filter impurities of different sizes in milk. The multi-layer screen design further realizes the graded treatment from coarse filtration to fine filtration. The stainless steel screen for milk filtering adopts a variety of aperture designs (such as 50μm, 100μm, 200μm, etc.), which can be flexibly selected according to needs, and can efficiently separate solid particles, milk agglomerates and impurities to meet the filtration needs of different stages.

The aperture of the stainless steel screen can be customized according to needs. While ensuring the filtration quality, the filtration efficiency needs to be improved as much as possible. The stainless steel filter screen optimizes the weaving method and opening rate of the screen to increase the passing speed of milk while ensuring the filtration accuracy.

Recommended mesh size of stainless steel sieve for filter milk

The following is a recommended table of commonly used mesh sizes of stainless steel sieves for filter milk. Different mesh sizes are suitable for different filter accuracy requirements:

|

Sieve mesh size (mesh) |

Corresponding aperture (μm) |

Filtering effect |

Applicable scenarios |

|

60 mesh |

≈ 250 μm |

Primary filtration, removal of larger particle impurities |

Preliminary filtration of fresh milk, on-site milk collection at the ranch |

|

80 mesh |

≈ 180 μm |

Medium filtration, removal of visible clots |

Small and medium-sized dairy processing plants |

|

100 mesh |

≈ 150 μm |

Fine filtration, retaining most of the milk fat |

Pre-pasteurization treatment |

|

120 mesh |

≈ 125 μm |

Remove fine particle impurities, moderately retain milk fat |

Before pasteurization and homogenization |

|

150 mesh |

≈ 100 μm |

Precision filtration, improve the cleanliness of dairy products |

High-end dairy product processing, such as yogurt, cheese, etc. |

|

200 mesh |

≈ 75 μm |

Ultrafine filtration, interception of fine impurities |

High hygiene requirements for dairy production lines, laboratory analysis pretreatment |

Application process of stainless steel sieve for filter milk

In the process of milk processing, in order to ensure quality and taste, it is usually necessary to go through a filtration step to remove impurities. After passing the milk through a stainless steel sieve for filter milk, lumps, solid impurities and some milk fat particles can be effectively removed, improving the homogeneity and purity of the milk. Stainless steel sieves play a key role in milk filtration. The main purpose of its application process is to remove impurities in milk and ensure the purity and quality of milk.

Preliminary filtration link in dairy processing plants

Filter protection device in milk delivery pipelines

During dairy product testing and quality control

In summary, the Stainless steel sieve for filter milk is a filtration equipment designed for milk processing. It is made of food-grade stainless steel. It removes impurities in milk through physical sieveing methods, improves product quality, and ensures the hygiene and safety of the processing process. Do you still want to know its specific model, mesh size or application equipment price?

-

Designed for precise grading, peeling or grading of wet

-

Granules, powders, and paddle materials can be used.

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Chemical liquid vibrating screen

Chemical liquid vibrating screen is a device used for solid-liquid separation or liquid filtration...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.