Salt Classifying with Vibro Sifter

What is a salt classifying with vibro sifter?

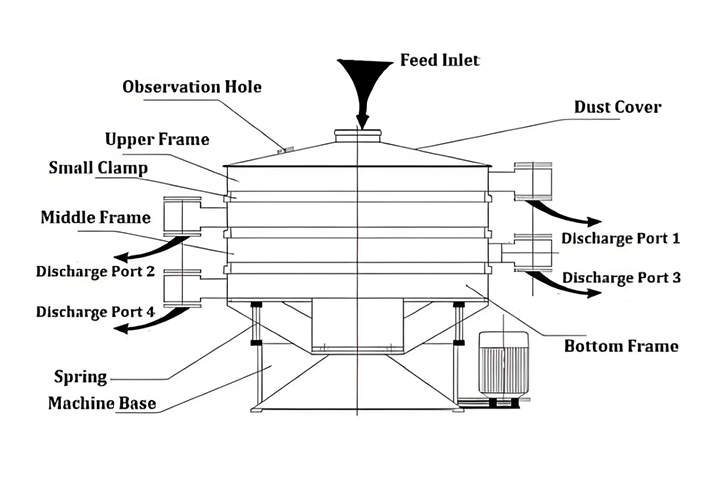

Salt classifying with vibro sifter refers to the process of using multiple layers of screens and specific mesh numbers to accurately classify raw salt according to particle size. According to the physical properties of different types of salt (such as table salt, sea salt, industrial salt), select the appropriate screen configuration, such as 20 mesh, 40 mesh, 60 mesh, 80 mesh, etc., to achieve effective separation of coarse salt, standard particle size salt and fine salt. The vibrating screen uses high-frequency vibration to make salt particles quickly pass through or stay in the corresponding screen layer, thereby achieving the purpose of particle size classification. It is suitable for multiple production links such as salt making, pre-packaging screening, impurity removal, etc.

Salt has the characteristics of strong hygroscopicity and easy agglomeration, and the particle size requirements of industrial salt and edible salt are very different. Salt classifying with vibro sifter solves these problems by adapting to sieves of different meshes. For example, 80-120 mesh sieves are often used to screen edible salt, which can obtain fine and uniform particles; 20-40 mesh sieves are suitable for coarse screening of industrial salt to remove larger impurities

Why choose a salt classifying with vibro sifter?

The salt classifying with vibro sifter is chosen because salt materials have special process requirements such as large particle size differences, easy moisture absorption and agglomeration, high hygiene requirements, and easy corrosion of equipment during the screening process, which are difficult to meet with ordinary screening equipment. The salt classifying with vibro sifter can efficiently achieve the classification, impurity removal, block breaking and dust removal of table salt, industrial salt, etc. through high-frequency vibration or linear vibration, improving product quality and production efficiency.

Salt classifying with vibro sifters usually adopt a multi-layer design and a large-diameter screen surface (such as 600mm, 1000mm, 1500mm, etc.), which can complete coarse screening and fine screening at one time, greatly improving the processing volume per unit time, and are suitable for screening scenes of materials such as table salt and industrial salt with strong continuity and high demand. Its high-speed vibration drives the material to pass through the screen quickly, reducing the material retention time and effectively improving the overall production capacity.

Salt Classification with Vibro Sifter Types

Linear vibrating screens are suitable for rapid coarse screening and medium-precision screening of salt. It has a large processing capacity and is suitable for salt with relatively uniform particles and good fluidity, such as sea salt and coarse salt.

The linear vibrating screen uses vibration force to cause salt particles to move linearly along the screen surface, reducing material accumulation and blockage, and improving screening efficiency. Circular vibrating screens are suitable for screening salt materials with high particle fineness such as fine salt and powder salt. Its screening action causes the salt particles to do a throwing motion on the screen surface, which is conducive to the screening of fine particles and improves the screening accuracy. The circular vibrating screen is suitable for the fine screening of food-grade salt to ensure the uniform particle size of the product.

The ultrasonic vibrating screen combines the mechanical vibration of the traditional vibrating screen with the ultrasonic high-frequency vibration, which can effectively prevent the adhesion between salt particles and the clogging of the screen. It is particularly suitable for the screening of wet salt or salt with high water content. The addition of ultrasonic waves improves the screening ability and screening efficiency of the screen, and is suitable for industrial salt and refined salt with extremely high screening accuracy requirements.

How Salt Classifying with Vibro Sifter Works

The material is fed evenly through the inlet and undergoes projectile and diffusion motion under the high-frequency vibration of the screen. Fine salt particles rapidly pass through the screen apertures under the action of gravity and centrifugal force, becoming qualified undersize material; coarse particles and agglomerates are blocked by the screen and separated and discharged as oversize material. For highly adhesive agglomerated salt, the vibration can break up the agglomerates, exposing their true particle size. Lightweight foreign matter such as plastic fibers float to the surface during vibration due to density differences and are collected and removed at the discharge end.

What can the salt classifying with vibro sifter be used for?

In the production process of crude salt, the salt classifying with vibro sifter can be used for preliminary screening to remove larger impurities such as stones, plant residues, etc., and classify the crude salt by size. For refined salt after processing, the salt classifying with vibro sifter can accurately classify according to the particle size. For example, in application scenarios such as food-grade salt and industrial salt that have specific requirements for particle size, the salt classifying with vibro sifter can be installed with multiple layers of screens as needed to complete the screening tasks of multiple particle size levels at one time.

Coarse salt screening: Usually a screen between 20 and 60 mesh is selected to effectively remove larger impurities and allow larger salt particles to pass through.

Refined salt grading: If it is refined salt for general food processing or industrial use, a screen of 80 to 120 mesh is required. For food-grade refined salt with higher requirements, a screen of 150 to 200 mesh is used. In some special applications, such as the pharmaceutical industry, a screen with a higher mesh number (such as 300 mesh or more) is required.

Moisture-proof and anti-caking treatment: Salt products used in humid environments are sometimes treated with finer screens to prevent agglomeration, which helps to disperse small particles that are easy to absorb moisture.

Application scenarios of vibrating screens in the field of salt screening

Salt Classifying with Vibro Sifter is widely used in the field of salt screening. In the production of table salt, the vibrating screen quickly separates coarse salt, fine salt and ultrafine salt through screens of different mesh sizes to ensure that the particle size of the finished salt is uniform; at the same time, it can remove impurities in the raw materials and improve the purity of the salt. In industrial salt processing, the vibrating screen can quickly screen large-particle salt to meet the specific requirements of chemical, metallurgical and other industries for salt particle size. Its high-frequency vibration design avoids salt particles clogging the mesh holes, and with anti-corrosion materials (such as stainless steel or plastic coating), it can adapt to high humidity and high salt corrosion environments. In addition, the vibrating screen is also used for the final screening of salt before packaging to ensure that no agglomerated salt enters the market, significantly improving production efficiency and product quality.

Salt classifying with vibro sifte price

The price of salt classifying with vibro sifter varies greatly due to different models, materials, mesh size and functional configurations. When purchasing, you need to pay attention not only to the applicability of the equipment and the subsequent maintenance costs, but also to comprehensively consider your actual needs, equipment quality, performance, after-sales service and other factors, so as to choose a product with high cost performance.

|

Type |

Applicable scenarios |

Reference price (US dollars) |

|

Small single-layer vibrating screen (diameter 400-600mm) |

Laboratory, manual salt screening, small batch production |

$500~$1,500 |

|

Standard three-dimensional vibrating screen (800-1200mm) |

Fine salt classification, table salt screening |

$1,500~$5,000 |

|

Multi-layer industrial vibrating screen (1200-1800mm) |

Large batch screening, multi-level classification |

$4,000~$10,000 |

|

Stainless steel anti-corrosion model |

Table salt, sea salt, pollution-free processing line |

$2,000~$8,000 |

|

Automatic feeding + screening integrated line |

Automated assembly line |

$8,000~$20,000 |

Salt Classifying with Vibro Sifter Case

Vibrating screens are widely used in the classification and screening of salt. According to the different particle sizes, they are divided into coarse salt, fine salt, ultrafine salt, dry salt and wet salt. Generally, the mesh size of coarse salt is 10-30, and linear vibrating screen is often used for preliminary screening; the mesh size of fine salt is 40-100, and rotary vibrating screen (three-dimensional vibrating screen) is suitable; the mesh size of ultrafine salt is 100-400 or above, and ultrasonic vibrating screen can be used; dry salt (extremely low moisture content) can use all types of vibrating screens; wet salt (high moisture content, easy to agglomerate) is suitable for dehydration vibrating screen or centrifugal screen. The following are the mesh size ranges of various types of salt and the applicable screening equipment:

|

Salt Type |

Mesh Range |

Suitable Screening Equipment |

Features |

|

Coarse Salt |

10-30 mesh |

Linear vibrating screen, Trommel screen |

High capacity, suitable for large particles |

|

Fine Salt |

40-100 mesh |

Rotary vibrating screen, Ultrasonic vibrating screen |

High precision, anti-clogging design |

|

Ultra-Fine Salt |

100-400 mesh |

Airflow sieve, Ultrasonic vibrating screen |

Specialized for fine powders, anti-static treatment |

|

Dry Salt |

Customizable |

All types of vibrating screens |

Requires dust-proof sealing design |

|

Wet Salt |

Customizable |

Dewatering vibrating screen, Centrifugal screen |

Requires corrosion-resistant materials and cleaning devices |

Salt classifying with vibro sifter is an indispensable and important equipment in salt production. It can not only improve the quality and market competitiveness of products, but also help enterprises optimize production processes and achieve the goal of energy conservation and emission reduction. Whether it is large-scale industrial production or small handicraft workshop, salt classifying with vibro sifter can provide an effective solution.

-

Granules, powders, and paddle materials can be used.

-

It can carry out 2-6 levels of screening and classification at the same time

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

Sieving Machine for Copper Electrolytic Powder

Sieving machine for copper electrolytic powder is a device used to screen copper powder obtained by electrolysis, which can...

-

What is the price of sesame vibro sifter?

The price of Sesame vibrating screen is around US$638 to US$1,700....

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.