100-mesh vibrating slip screen

What is a 100-mesh vibrating slip screen?

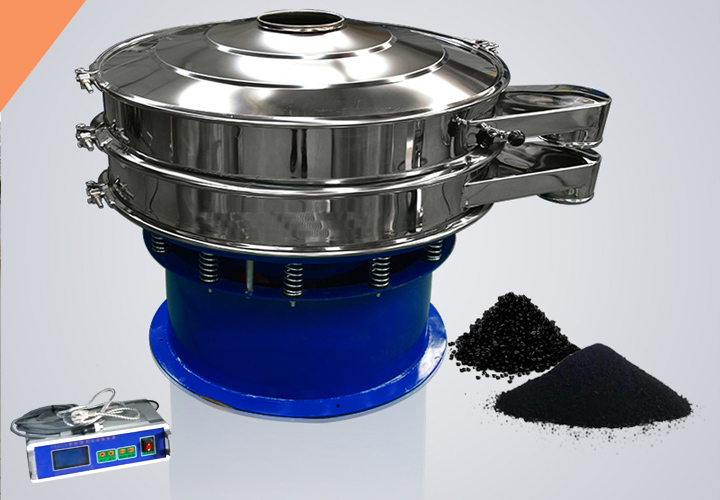

100-mesh vibrating slip screen are available in carbon steel or stainless steel, depending on the specific characteristics of the material being screened.

100-mesh vibrating slip screen effectively separates fine particles (less than 0.15 mm) from coarse particles (larger than 0.15 mm). It is suitable for classifying micropowders and fine particles. It is a high-precision, efficient screening device. By combining a 100-mesh screen with vibration technology, it accurately classifies fine particles. Typically made of woven stainless steel or polyurethane, it offers excellent wear resistance and long service life. It is an essential device for separating fine particles, improving material quality, and improving production efficiency.

How to choose a 100-mesh vibrating slip screen?

The selection of a 100-mesh vibrating slip screen depends on the material characteristics: For granular or powdered materials, a circular vibrating screen offers excellent screening accuracy. For slurries, a filter screen is recommended, as its anti-clogging design ensures liquid-solid separation. For food products, a full stainless steel screen is recommended, while for chemicals, carbon steel is recommended. For highly corrosive materials, polypropylene or corrosion-resistant stainless steel is recommended to extend the life of the equipment.

What are the advantages of 100-mesh vibrating slip screen?

The 100-mesh vibrating slip screen efficiently separates fine particles through a fine mesh, improving liquid purity and clarity, preventing downstream clogging, and utilizing enhanced vibration to promote fine particle movement for separation.

Enhanced fine particle separation: The equipment is able to efficiently separate relatively fine solid particles (usually larger than about 150 microns) from liquids or slurries. This separation effect is significantly higher than those coarse mesh vibrating screens (such as 40 mesh, 60 mesh) used to remove larger solid particles.

Increase product clarity and purity: By removing these finer suspended solids, the 100-mesh vibrating slip screen helps produce a clearer, purer liquid product with better visual appeal and potentially better downstream processing characteristics.

Prevent downstream problems: Removing particles around 100 mesh can prevent finer downstream equipment from clogging or damage, allowing medium-sized fine powders to pass through.

Enhanced vibration for fine separation: The vibration system used with the 100-mesh slip screen is usually designed with a higher frequency or specific vibration mode that can more effectively keep the fine mesh open and promote the movement of finer particles.

100-mesh vibrating slip screen technical parameters

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-1000 | 1000 | <10 | <1500 | 1-5 | 0.75 | 800 |

How does the 100-mesh vibrating slip screen work?

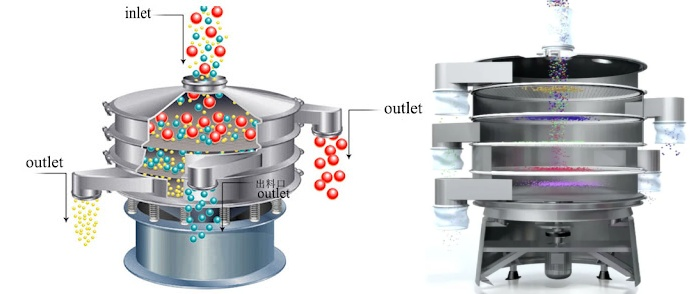

100-mesh vibrating slip screen: During screening, the material moves from top to bottom according to the direction. Under the working principle, some functions can be added, such as crushing function, dust collection function and ultrasonic function.

Vibration: A motor or vibrator generates high-frequency vibrations and transmits them to the screen surface, generating intense vibration energy in the screen mesh. This causes the material to continuously shake and tumble on the screen surface, accelerating particle screening efficiency.

Lifting and Lowering: Particles are repeatedly lifted by the vibration force and then freely fall back onto the screen surface. This up-and-down motion not only promotes even material distribution but also increases contact between particles and the screen mesh, thereby improving screening accuracy and efficiency.

Forward Motion: The 100-mesh vibrating slide screen uses the forward force generated by vibration to move the material forward along the screen surface, typically in a linear or circular motion. This ensures that the material continuously passes across the entire screen surface, achieving continuous screening.

Stratification: During the vibration process, the material naturally stratifies according to particle size, density, and shape. Lighter or smaller particles easily move to the bottom and pass through the screen mesh, while heavier or larger particles are retained at the top of the screen, achieving efficient and fine grading and screening.

What are the Applications of 100-mesh vibrating slip screen?

100-mesh vibrating slip screen is a kind of equipment widely used in particle material classification, solid-liquid separation and screening operations. Its core feature is that the mesh aperture is 100 mesh (that is, there are 100 mesh holes per inch length), which is suitable for scenes with finer material particle size requirements.

Screening of fine chemical raw materials

In the production of dyes, pigments, catalysts, etc., raw materials need to be graded according to particle size to ensure product quality. 100-mesh screen can effectively separate particles with a particle size of about 150 microns, and remove impurities or materials that do not meet the particle size requirements.

Regeneration and recovery of activated carbon

Vibrating slip screen is used for deashing and desludging of activated carbon. 100-mesh screen can intercept fine impurities and allow regenerated activated carbon to pass through, thereby improving recovery efficiency.

Production of food additives and seasonings

In the production of salt, sugar, spices, etc., 100-mesh screen can ensure uniform product particle size and prevent large particles from affecting taste or solubility. For example, it is used to remove lumps or foreign matter in milk powder production.

Feed raw material screening

In the production of fish meal, soybean meal and other feed raw materials, 100-mesh vibrating slip screen can remove impurities and lumps, ensure uniform feed particle size, and improve animal digestion and absorption rate.

100-mesh vibrating slip screen customer case study

A ceramic raw material processing company introduced our 100-mesh vibrating slip screen to improve powder screening efficiency. Driven by a high-frequency vibration motor and equipped with a 304 stainless steel screen, the device effectively solves the problems of screen clogging and low efficiency associated with traditional screening.

Application results: Processing capacity reaches 3 tons/hour, screening accuracy reaches 98%, and product uniformity is significantly improved. The fully enclosed structure reduces dust escape, meeting environmental requirements. The modular design allows for quick screen replacement, reducing maintenance costs by 30%.

Customer feedback: The device operates stably, increases production capacity by 40%, significantly reduces manual intervention, and successfully replaces the existing drum screen, becoming a key piece of equipment in the production line.

What is the difference between 40 mesh screen and 100-mesh vibrating slip screen?

The main difference between a 40-mesh screen and a 100-mesh vibrating slip screen is the size of the screen holes, which directly affects their particle retention capacity, application range, and processing efficiency.

Mesh size and particle retention

40 mesh screen: has 40 openings per linear inch, resulting in a larger aperture size, allowing smaller particles to pass through.

100 mesh vibrating slide screen: has 100 openings per linear inch, with significantly smaller aperture size, providing finer filtration.

Scope of application

40 mesh screen: suitable for coarse screening tasks to separate larger particles, such as mining, agriculture or construction.

100 mesh vibrating slip screen: suitable for fine screening applications, including chemical processing, pharmaceutical and food production.

Processing efficiency and material flow

40 mesh screen: can handle higher throughput, resulting in faster material flow and reduced risk of clogging.

100 mesh vibrating slide screen: the screen is finer, the material processing speed is slower, and vibration is required to prevent the screen holes from clogging.

100-mesh vibrating slip screen stands out from other vibrating screens due to its unique design and performance characteristics, designed for fine particle separation (approximately 150 microns) and processing of difficult materials.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor.

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

Desert sand sieving machine

Desert sand sieving machine is a mechanical equipment used for sand and gravel processing or sieving...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Vibrating screen for coal gangue screening

Z-type bucket elevator for peanut conveying is a vertical lifting equipment specially designed for fragile or soft conveying...

-

Filtering-Soya-Bean-Milk-screen

Filtering soya bean milk screen is a device specially used to separate soya milk from bean dregs. It filters out the solid residue...

-

Why use gas protection ultrasonic sieving machine metal powder?

The specific gravity of metal powder is light and easy to Due to static electricity problem, it is difficult for general vibrating screen to screen effectively ...

-

How much is an abrasive automatic sieving machine?

Abrasive automatic sieving machine is a commonly used industrial powder sieving equipment, widely used in metallurgy...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.